|

Groove diameter

|

Shaft diameter range

|

Lock washer

|

Groove

|

Supplementary data

|

||||||||||||||

|

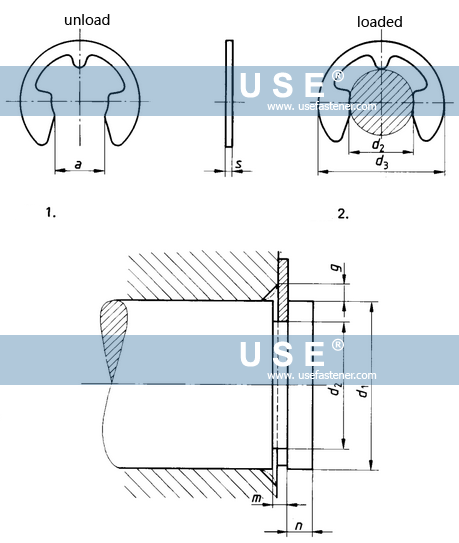

d2

|

d1

|

s

|

|

a

|

|

d2

|

m

|

n

|

d3

|

FN

|

FS

|

g

|

Fsg

|

nab1

|

||||

|

Nominal size

|

from

|

to

|

|

per.dev.

|

|

per.dev.(±IT 10)

|

|

per.dev.(h 11)

|

|

per.dev.

|

min.

|

max.

|

Kn

|

at, d1

|

Kn

|

|

Kn

|

min,-1

|

|

0.8

|

1

|

1.4

|

0.2

|

±0.02

|

0.58

|

±0.04

|

0.8

|

0

-0.04 |

0.24

|

+0.04

0 |

0.4

|

2.25

|

0.03

|

1.2

|

0.08

|

0.3

|

0.04

|

50000

|

|

1.2

|

1.4

|

2

|

0.3

|

1.01

|

1.2

|

0

-0.06 |

0.34

|

0.6

|

3.25

|

0.04

|

1.5

|

0.12

|

0.4

|

0.06

|

47000

|

|||

|

1.5

|

2

|

2.5

|

0.4

|

1.28

|

1.5

|

0.44

|

0.8

|

4.25

|

0.07

|

2

|

0.22

|

0.6

|

0.11

|

43000

|

||||

|

1.9

|

2.5

|

3

|

0.5

|

1.61

|

1.9

|

0.54

|

+0.05

0 |

1

|

4.8

|

0.10

|

2.5

|

0.30

|

0.7

|

0.17

|

40000

|

|||

|

2.3

|

3

|

4

|

0.6

|

1.94

|

2.3

|

0.64

|

1

|

6.3

|

0.15

|

3

|

0.50

|

0.9

|

0.24

|

38000

|

||||

|

3.2

|

4

|

5

|

0.6

|

2.70

|

3.2

|

0

-0.075 |

0.64

|

1

|

7.3

|

0.22

|

4

|

0.65

|

0.9

|

0.32

|

35000

|

|||

|

4

|

5

|

7

|

0.7

|

3.34

|

±0.048

|

4

|

0.74

|

1.2

|

9.3

|

0.25

|

5

|

0.95

|

1

|

0.47

|

32000

|

|||

|

5

|

6

|

8

|

0.7

|

4.11

|

5

|

0.74

|

1.2

|

11.3

|

0.90

|

7

|

1.15

|

1

|

0.60

|

28000

|

||||

|

6

|

7

|

9

|

0.7

|

5.26

|

6

|

0.74

|

1.2

|

12.3

|

1.10

|

8

|

1.35

|

1.1

|

0.70

|

25000

|

||||

|

7

|

8

|

11

|

0.9

|

5.84

|

7

|

0

-0.09 |

0.94

|

1.5

|

14.3

|

1.25

|

9

|

1.80

|

1.3

|

1.00

|

22000

|

|||

|

8

|

9

|

12

|

1

|

±0.03

|

6.52

|

±0.058

|

8

|

1.05

|

+0.08

0 |

1.8

|

16.3

|

1.42

|

10

|

2.50

|

1.5

|

1.25

|

20000

|

|

|

9

|

10

|

14

|

1.1

|

7.63

|

9

|

1.15

|

2

|

18.8

|

1.60

|

11

|

3.00

|

1.6

|

1.50

|

17000

|

||||

|

10

|

11

|

15

|

1.2

|

8.32

|

10

|

1.25

|

2

|

20.4

|

1.70

|

12

|

3.50

|

1.8

|

1.75

|

15000

|

||||

|

12

|

13

|

18

|

1.3

|

10.45

|

±0.07

|

12

|

0

-0.11 |

1.35

|

2.5

|

23.4

|

3.10

|

15

|

4.70

|

1.9

|

2.30

|

13000

|

||

|

15

|

16

|

24

|

1.5

|

12.61

|

15

|

1.55

|

3

|

29.4

|

7.00

|

20

|

7.80

|

2.2

|

3.30

|

11000

|

||||

|

19

|

20

|

31

|

1.75

|

15.92

|

19

|

0

-0.13 |

1.80

|

3.5

|

37.6

|

10.00

|

25

|

11.00

|

2.5

|

3.60

|

7600

|

|||

|

24

|

25

|

38

|

2

|

21.88

|

±0.084

|

24

|

2.05

|

4

|

44.6

|

13.00

|

30

|

15.00

|

3

|

4.00

|

5500

|

|||

|

30

|

32

|

42

|

2.5

|

25.80

|

30

|

2.55

|

4.5

|

52.6

|

16.50

|

36

|

23.00

|

3.5

|

5.30

|

4200

|

||||