HRC 58-62

|

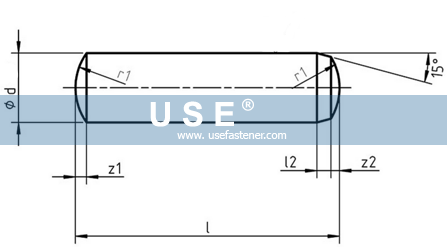

d

(m6) |

0.8

|

1

|

1.5

|

2

|

2.5

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

14

|

16

|

20

|

|

l2

|

0.4

|

0.4

|

0.5

|

0.6

|

0.7

|

0.8

|

1

|

1.2

|

1.5

|

1.8

|

2

|

2.5

|

2.5

|

3

|

4

|

|

r? ≈

|

0.8

|

1

|

1.6

|

2

|

2.5

|

3

|

4

|

5

|

6

|

8

|

10

|

12

|

16

|

16

|

20

|

|

z1 ≈

|

0.12

|

0.15

|

0.23

|

0.3

|

0.4

|

0.45

|

0.6

|

0.75

|

0.9

|

1.2

|

1.5

|

1.8

|

2

|

2.5

|

3

|

|

z2 ≈

|

0.06

|

0.08

|

0.12

|

0.18

|

0.25

|

0.3

|

0.4

|

0.5

|

0.6

|

0.8

|

1

|

1.3

|

1.3

|

1.7

|

2

|