|

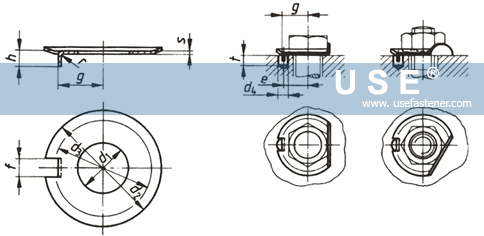

d1

|

d2

|

d3 ≈

|

f

|

g

|

h ≈

|

r

|

s

|

d4

|

e

|

t

|

For thread diameter

|

|

3.2

|

12

|

8

|

2.5

|

4.5

|

2

|

0.4

|

0.4

|

4

|

4.3

|

2.5

|

3

|

|

3.7

|

12

|

8

|

2.5

|

4.5

|

2

|

0.4

|

0.4

|

4

|

4.3

|

2.5

|

3.5

|

|

4.3

|

14

|

10

|

2.5

|

5.5

|

2

|

0.4

|

0.4

|

4

|

5.3

|

2.5

|

4

|

|

5.3

|

17

|

12

|

3.5

|

7

|

2.5

|

0.6

|

0.75

|

5

|

6.62

|

3.5

|

5

|

|

6.4

|

19

|

14

|

3.5

|

7.5

|

3

|

0.6

|

0.75

|

5

|

7.12

|

3.5

|

6

|

|

7.4

|

19

|

14

|

3.5

|

7.5

|

3

|

0.6

|

0.75

|

5

|

7.12

|

3.5

|

7

|

|

8.4

|

22

|

16

|

3.5

|

8.5

|

4

|

1

|

1

|

5

|

8

|

4

|

8

|

|

10.5

|

26

|

20

|

4.5

|

10

|

4

|

1

|

1

|

6

|

9.5

|

4

|

10

|

|

13

|

30

|

24

|

4.5

|

12

|

4.5

|

1

|

1.2

|

6

|

11.4

|

5

|

12

|

|

15

|

33

|

27

|

4.5

|

13

|

4.5

|

1

|

1.2

|

6

|

12.4

|

5

|

14

|

|

17

|

36

|

30

|

5.5

|

15

|

4.5

|

1

|

1.2

|

7

|

14.4

|

5

|

16

|

|

19

|

40

|

34

|

6.5

|

18

|

4.5

|

1

|

1.2

|

8

|

17.4

|

5

|

18

|

|

21

|

42

|

36

|

6.5

|

18

|

4.5

|

1

|

1.6

|

8

|

17.2

|

5

|

20

|

|

23

|

50

|

43

|

7.5

|

20

|

6.5

|

1

|

1.6

|

9

|

19.2

|

7

|

22

|

|

25

|

50

|

43

|

7.5

|

21

|

6.5

|

1

|

1.6

|

9

|

20.2

|

7

|

24

|

|

28

|

58

|

50

|

8.5

|

23

|

9.5

|

1

|

1.6

|

10

|

22.2

|

9

|

27

|

|

31

|

63

|

55

|

8.5

|

25

|

9.5

|

1

|

1.6

|

10

|

24.2

|

9

|

30

|

|

34

|

68

|

60

|

9.5

|

28

|

9.5

|

1

|

1.6

|

11

|

27.2

|

9

|

33

|

|

37

|

75

|

67

|

11

|

31

|

9.5

|

1

|

2

|

13

|

30

|

9

|

36

|

|

40

|

82

|

74

|

11

|

33

|

11

|

1

|

2

|

13

|

32

|

11

|

39

|

|

43

|

88

|

80

|

11

|

36

|

11

|

1

|

2

|

13

|

35

|

11

|

42

|

|

46

|

95

|

85

|

13

|

38

|

12

|

1

|

2

|

15

|

37

|

12

|

45

|

|

50

|

100

|

90

|

13

|

40

|

13

|

1

|

2

|

15

|

39

|

13

|

48

|

|

54

|

105

|

95

|

13

|

42

|

13

|

1

|

2

|

15

|

41

|

13

|

52

|

|

58

|

112

|

102

|

16

|

45

|

14

|

1.6

|

2.5

|

18

|

43.75

|

14

|

56

|

|

62

|

118

|

108

|

16

|

48

|

13.5

|

1.6

|

2.5

|

18

|

46.75

|

14

|

60

|

|

66

|

125

|

115

|

18

|

52

|

13.5

|

1.6

|

2.5

|

20

|

50.75

|

14

|

64

|

|

70

|

132

|

122

|

18

|

55

|

14

|

1.6

|

2.5

|

20

|

53.75

|

16

|

68

|

|

74

|

138

|

128

|

18

|

58

|

14

|

1.6

|

2.5

|

20

|

56.75

|

16

|

72

|

|

78

|

145

|

135

|

21

|

60

|

14

|

1.6

|

2.5

|

23

|

58.75

|

16

|

76

|

|

82

|

150

|

140

|

21

|

62

|

16

|

1.6

|

2.5

|

23

|

60.75

|

18

|

80

|

|

93

|

165

|

155

|

23

|

70

|

15.5

|

1.6

|

2.5

|

25

|

78.75

|

18

|

90

|

|

104

|

185

|

175

|

23

|

80

|

15.5

|

1.6

|

2.5

|

25

|

78.75

|

18

|

100

|