|

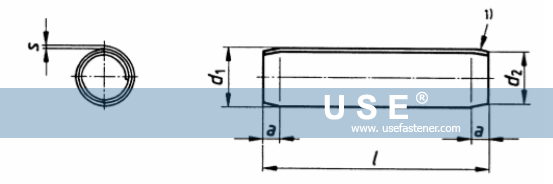

d1 |

before mounting |

nominal |

0.8 |

1 |

1.2 |

1.5 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

|

max. |

0.91 |

1.15 |

1.35 |

1.73 |

2.25 |

2.78 |

3.3 |

3.84 |

4.4 |

5.5 |

6.5 |

8.63 |

10.8 |

12.85 |

14.95 |

17 |

21.1 |

||

|

min. |

0.85 |

1.05 |

1.25 |

1.62 |

2.13 |

2.65 |

3.15 |

3.67 |

4.2 |

5.25 |

6.25 |

8.3 |

10.35 |

12.4 |

14.45 |

16.45 |

20.4 |

||

|

d2 |

before mounting |

max. |

0.75 |

0.95 |

1.15 |

1.4 |

1.9 |

2.4 |

2.9 |

3.4 |

3.9 |

4.85 |

5.85 |

7.8 |

9.75 |

11.7 |

13.6 |

15.6 |

19.6 |

|

a ≈ |

approx. |

0.3 |

0.3 |

0.4 |

0.5 |

0.7 |

0.7 |

0.9 |

1 |

1.1 |

1.3 |

1.5 |

2 |

2.5 |

3 |

3.5 |

4 |

4.5 |

|

|

s |

0.07 |

0.08 |

0.1 |

0.13 |

0.17 |

0.21 |

0.25 |

0.29 |

0.33 |

0.42 |

0.5 |

0.67 |

0.84 |

1 |

1.2 |

1.3 |

1.7 |

||

|

Minimum shear strength. double. kN |

a |

0.4 |

0.6 |

0.9 |

1.45 |

2.5 |

3.9 |

5.5 |

7.5 |

9.6 |

15 |

22 |

39 |

62 |

89 |

120 |

155 |

250 |

|

|

b |

0.3 |

0.45 |

0.65 |

1.05 |

1.9 |

2.9 |

4.2 |

5.7 |

7.6 |

11.5 |

16.8 |

30 |

48 |

67 |

- |

- |

- |

||

|

l |

|

||||||||||||||||||

|

nominal |

min. |

max. |

|||||||||||||||||

|

4 |

3.75 |

4.25 |

√ |

√ |

√ |

√ |

√ |

||||||||||||

|

5 |

4.75 |

5.25 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

6 |

5.75 |

6.25 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||

|

8 |

7.75 |

8.25 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

10 |

9.75 |

10.25 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||

|

12 |

11.5 |

12.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

14 |

13.5 |

14.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

16 |

15.5 |

16.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||

|

18 |

17.5 |

18.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

20 |

19.5 |

20.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||

|

22 |

21.5 |

22.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||

|

24 |

23.5 |

24.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

26 |

25.5 |

26.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||

|

28 |

27.5 |

28.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

30 |

29.5 |

30.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

32 |

31.5 |

32.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||

|

35 |

34.5 |

35.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||

|

40 |

39.5 |

40.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||

|

45 |

44.5 |

45.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||||

|

50 |

49.5 |

50.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

55 |

54.25 |

55.75 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

60 |

59.25 |

60.75 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

65 |

64.25 |

65.75 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||||

|

70 |

69.25 |

70.75 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||||

|

75 |

74.25 |

75.75 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||||

|

80 |

79.25 |

80.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

85 |

84.25 |

85.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

90 |

89.25 |

90.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

95 |

94.25 |

95.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

100 |

99.25 |

100.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

120 |

119.25 |

120.75 |

√ |

√ |

√ |

√ |

√ |

√ |

|||||||||||

|

140 |

139.25 |

140.75 |

√ |

√ |

√ |

√ |

|||||||||||||

|

160 |

159.25 |

160.75 |

√ |

√ |

√ |

√ |

|||||||||||||

|

180 |

179.25 |

180.75 |

√ |

√ |

√ |

||||||||||||||

|

200 |

199.25 |

200.75 |

√ |

√ |

√ |

||||||||||||||