|

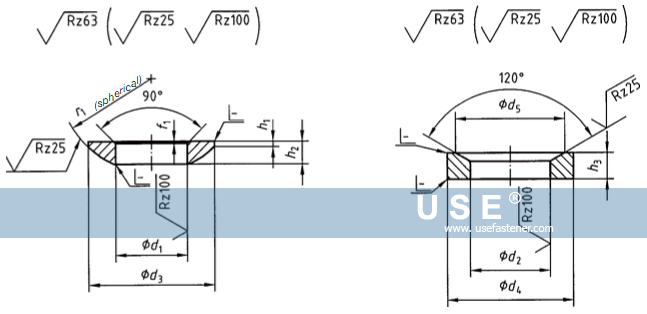

d1

|

d2

|

d3

|

d4 Types

|

d5

|

f1

|

h1

|

h2

|

h3 Types

|

r1(spherical)

|

Thread size

|

Maximum bolting force, in K

|

||

|

D

|

G

|

≈

|

D

|

G

|

|||||||||

|

6.4

|

7.1

|

12

|

12

|

17

|

11

|

0.3

|

0.7

|

2.3

|

2.8

|

4

|

9

|

M6

|

9

|

|

8.4

|

9.6

|

17

|

17

|

24

|

14.5

|

0.5

|

0.6

|

3.2

|

3.5

|

5

|

12

|

M8

|

17

|

|

10.5

|

12

|

21

|

21

|

30

|

18.5

|

0.5

|

0.8

|

4

|

4.2

|

5

|

15

|

M10

|

26

|

|

13

|

14.2

|

24

|

24

|

36

|

20

|

0.5

|

1.1

|

4.6

|

5

|

6

|

17

|

M12

|

38

|

|

15

|

16.5

|

28

|

28

|

40

|

24.8

|

0.5

|

1.2

|

5

|

5.6

|

6

|

22

|

M14

|

53

|

|

17

|

19

|

30

|

30

|

44

|

26

|

0.5

|

1.3

|

5.3

|

6.2

|

7

|

22

|

M16

|

73

|

|

21

|

23.2

|

36

|

36

|

50

|

31

|

0.5

|

2

|

6.3

|

7.5

|

8

|

27

|

M20

|

117

|

|

25

|

28

|

44

|

44

|

60

|

37

|

0.8

|

2.4

|

8.2

|

9.5

|

10

|

32

|

M24

|

168

|

|

31

|

35

|

56

|

56

|

68

|

49

|

0.8

|

3.6

|

11.2

|

12

|

12

|

41

|

M30

|

269

|

|

37

|

42

|

68

|

68

|

/

|

60

|

1

|

4.6

|

14

|

15

|

/

|

50

|

M36

|

394

|

|

43

|

49

|

78

|

78

|

/

|

70

|

1

|

6.5

|

17

|

18

|

/

|

58

|

M42

|

542

|

|

50

|

56

|

92

|

92

|

/

|

82

|

1

|

8

|

21

|

22

|

/

|

67

|

M48

|

714

|